Introducing displays that combine high functionality with outstanding design in glass or plastic

YOSHIDA TECHNOWORKS empowers your success

As the electrification of the auto industry gathers speed, the need for interior displays with higher functionality and more sophisticated design is increasing.

Larger displays with a curved design must still be safe and reliable.

With our unique expertise centered on the world’s first In-mold Decoration technology, YOSHIDA TECHNOWORKS offers precise solutions to a wide range of automotive device requirements.

Mass production experience of in-vehicle CID cover panels for Japanese automotive manufacturers

Select the best film for the job: film (In-mold Decoration foil) that can follow sharper, deeper-drawn geometry, AG film or AF film for its LCD-compatibility, or an AR film that meets the desired spec level. Then, we propose the optimal molding process: In-mold Decoration, double-sided In-mold Decoration, insert molding, and more.

With mass production experience of in-vehicle CID cover panels for Japanese automotive manufacturers, YOSHIDA TECHNOWORKS delivers reliably high-quality products in both plastic and glass.

For plastic

Our unique, special techniques eliminate retardation in transparent sections.

Our high-yield double-sided In-mold Decoration process produces a deep, piano-black design.

For glass

Integral molding with a plastic bezel results in narrower frames. The additional ribs and bosses on the rear surface of the plastic bezel makes for improved alignment during assembly and easy reworking of the main body.

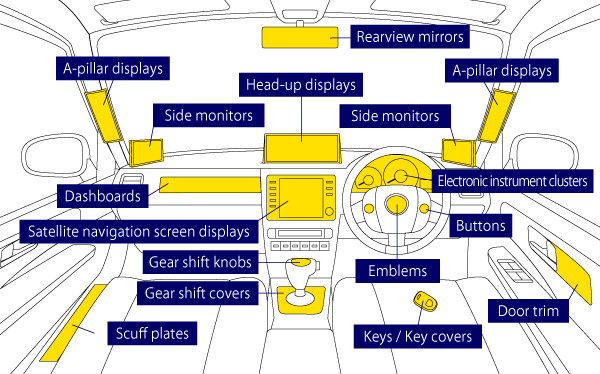

YOSHIDA technologies in automotive devices

General In-mold Decoration

- Dashboards

- Gear shift knobs

- Gear shift covers

- Door trim

- Buttons

- Keys / Key covers

Application of decoration during the molding process reduces the number of total process steps and cost.

Learn more >

Glass Insert Molding with In-mold Decoration

- Side monitors

- Rearview mirrors

- Head-up displays

- Electronic instrument clusters

- Satellite navigation screen displays

This technology enables integral molding of glass and resins and the In-mold Decoration of the resin film during the injection process.

Shaving down the edges for a virtually frame-less design makes it possible to offer a bigger display area.

This technique can also be applied to curved glass.

Learn more >

AR, AG, and AF In-mold Decoration

- Side monitors

- Rearview mirrors

- Head-up displays

- Electronic instrument clusters

- Satellite navigation screen displays

- A-pillar displays

Anti-reflection (AR), anti-glare (AG) and anti-fingerprint (AF) coatings are transferred to the surface during the injection process making it possible to follow the gentlest of curves.

AR, AG and AF coatings can be applied individually or in any combination.

Learn more >

EF Insert In-mold

- Gear shift knobs

- Emblems

- Keys / Key covers

Since insert molding is carried out inside a real metal mold, the result has a genuinely luxurious feel.

Plating Insert In-mold

- Dashboards

- Gear shift knobs

- Keys / Key covers

Insert molding with plastic parts plated with metal.

Black hole illumination

Double-sided In-mold Decoration of a half mirror and a full mirror creates a design that reflects light repeatedly, giving an appearance of multiple layers.

Dead front sheet inserts

Information and designs not visible under normal conditions are rendered visible by LED lighting.